A golden opportunity presented itself this April to some Rotarians from the food processing industry in D 3170, when they were trained in different facets of this industry in D 7360, USA. The States of Pennsylvania, Maryland and West Virginia are important contributors to the US economy in agricultural produce, grain processing, horticulture, fruit processing, dairy farming and value addition to milk and fruits.

The Rotarians who underwent training in modern aspects of food production and food processing and other associated activities included Ashok Habib (RC Sirsi), a first generation entrepreneur owning a modern desiccated coconut flakes manufacturing unit; Amit Mate of RC Kolhapur, a technocrat specialising in automation and developing system controls in food industry; Supriya Jadhav, sponsored by RC Sangli, a baker owning a café in Sangli and Pune; Ramanagauda Timmanayakar, sponsored by RC Bagalkote, an agriculturist who has developed a unique method of manufacturing pomegranate juice and promotes the use of a multi- grain flour made from cereals, millets and legume seeds which have a low glycemic index and hence is good for diabetics; and Vishwajit Shinde, sponsored by RC Kolhapur Sunrise, a sugar technologist.

The team visited the UTZ Quality Foods Inc. which manufactures a wide variety of potato chips (450,000 kg) and pretzels (410,000 kg) every week. From the special glass observation gallery at its 600,000 sq ft facility, we watched the whole procedure, being guided step-by-step with the aid of a push-to-talk audio programme and closed-circuit TV monitors.

At Zoe’s Chocolates we saw a time-honoured tradition meet modern sophistication in chocolate making. A three-generation company, Zoe’s Chocolates combines the spirit, skill and tradition of past generations. Everything is fresh and natural, made from sustainable products, from nearby farms, like fresh cream, eggs, butter and pure honey.

At Misty Meadows Farm Creamery, Smithsburg, Maryland, a family-run farm owned by David and Betsy Herbst, we were taken around in a tractor-driven trolley, where we saw the creamery in action. They have a herd of 400 Holstein Friesian cows and own about 4,000 acres of farmland on which they grow forage grass and corn.

The cows are fed a total mixed ration (TMR) formulated by a cow dietitian that includes corn, grass, as well as shelled corn and soybean meal and minerals needed to balance the animals’ diet. The average production of milk here is about 16,000 litres a day. While they sell fresh milk to cooperative dairies, they convert most of their milk into dairy products like ice cream, cheese or yogurt.

At the Adam’s County Winery, Rtn John and Katherine Kramb grow Chardonnay and Cabernet Sauvignon grapes for wine making and other fruits like peach, apricot, strawberries, mulberries and blueberries for various other fruit products. From the harvesting of grapes, fermentation, filtration and bottling, we got to see it all at this master wine maker.

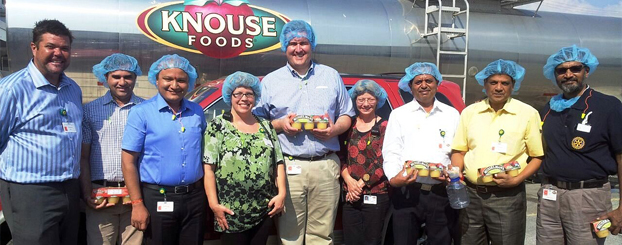

At Knouse Foods, a growers’ cooperative with a 50-year history of providing the best fruit products, apple sauce is manufactured. Here we saw 18 controlled atmosphere rooms which regulate temperature, humidity, oxygen and carbon dioxide content. Each room holds 31 tractorloads of apples, kept under conditions which allow them to retain their crispness, juice and flavour for up to a year after harvesting.

Robotic milking

The visit to Carol and Carl’s Dairy Farm, Chambersburg, was a total surprise. We never expected this elderly couple to manage a dairy farm with 260 cows. They’ve changed from manual to robotic milking system seven years ago, and told us the cows took just a week to adjust to the robotic milking method! Their cows come in from pasture, walk through the gates into the commitment pen to the robot for milking and eat a grain ration that is computed according to the animal’s milk yield and health status. The cows can now be milked day or night, up to six times in 24 hours, if they choose. Yes, the cows can actually choose when they want to be milked. The result: Production has increased at least 10–15 per cent, without compromising on quality.

The robot is flexible and fully trained to prepare the cows for milking, to clean their teats before and after milking, to attach the teat-cups, to reattach them if required, and to detach them after milking.

At the Trickling Springs Creamery, Chambersburg, a cooperative dairy, that specialises in processing ‘organic milk,’ the farmers are shareholders and committed to maintaining pasture-grazed dairy cows, which are never fed any grain or cattle feed. Milk is purchased from local family farms who take special interest in the welfare of the grass-fed cows by using organic and holistic practices.

This dairy processes milk using a low temperature pasteurisation method that allows the milk’s natural proteins and enzymes to live, giving healthier milk and tastier ingredients. They sell ‘organic and all natural’ milk in returnable glass bottles, and also produce cultured buttermilk, homemade butters, raw milk cheeses and more than 25 flavours of premium ice-creams. They’ve also started to promote goats’ milk and cheese.

Hamilton Heights Dairy Farm, Chambersburg, PA owned by a seasoned farmer couple Clifford and Daisy Hawbaker, this farm produces only ‘organic milk.’ No-concentrate feed made from grains/cereals/pulses or oilseeds is used for their cows. The team learnt the new concept of ‘pasture management’ which is of great value for Indian dairy farmers. The farmer converts most of the excess grass that he cultivates into hay to be used during the harsh winters when there is shortage of grass.

Our visit to the Appalachian Brewing Company, Harrisburg, gave us an insight into the ‘art’ of beer making. We learnt how the colour of beer is directly influenced by the colour of grains and the malt used. Grain, hops, water and yeast are very important for a correct brew.

At the TRÖEGS Independent Craft Brewery, the focus is on the production of specialty and seasonal beers. Their bottling plant packs 230 bottles per minute.

This VTT programme was a truly memorable experience for all of us. Thanks to the opportunity provided by D 3170, D 7360 and TRF. We also made many new friends beyond our shores, and came closer to the larger Rotary family.

(The writer is member of

RC Bhatkal, D 3170 and the VTT’s team leader)