When earthquakes devastated villages across the island of Lombok, Indonesia, in 2018, the collapse of homes and school buildings displaced thousands of people and temporarily stopped the education of 4,000 students. The clean-up and restoration efforts have taken years. But an Australian-based charity has found a novel solution to rebuilding destroyed buildings quickly, while also recycling plastic waste along the way.

Classroom of Hope builds sustainable schools and homes that are safe and secure for communities in developing countries to help students return to their education quicker. Founded in 2012 by Duncan Ward and his wife Nicola Courtin, Classroom of Hope has built 77 schools in Cambodia, Laos, and Myanmar, and is now focused on rebuilding schools in Indonesia.

“50,000 children have had to learn in temporary facilities since the 2018 Lombok earthquakes that destroyed over 400 schools,” said Duncan, CEO of the organisation.

“A child in a temporary school learns half as much as she would in a permanent school, with the loss of learning costing the Lombok economy up to $72 million per year in future productivity.”

When the small village of Taman Sari in Lombok was devastated by the earthquakes in 2018, Classroom of Hope joined the relief effort to help the village build temporary school buildings to get children back into education while a longer-term solution was developed.

That solution came in the form of the revolutionary Block Solutions system, which takes plastic waste and turns it into lightweight, interconnecting blocks that build earthquake-resistant buildings.

Finland-based company Block Solutions uses its recycled plastic block technology for housing projects in Africa and has partnered with Classroom of Hope to bring its Block system to Indonesia.

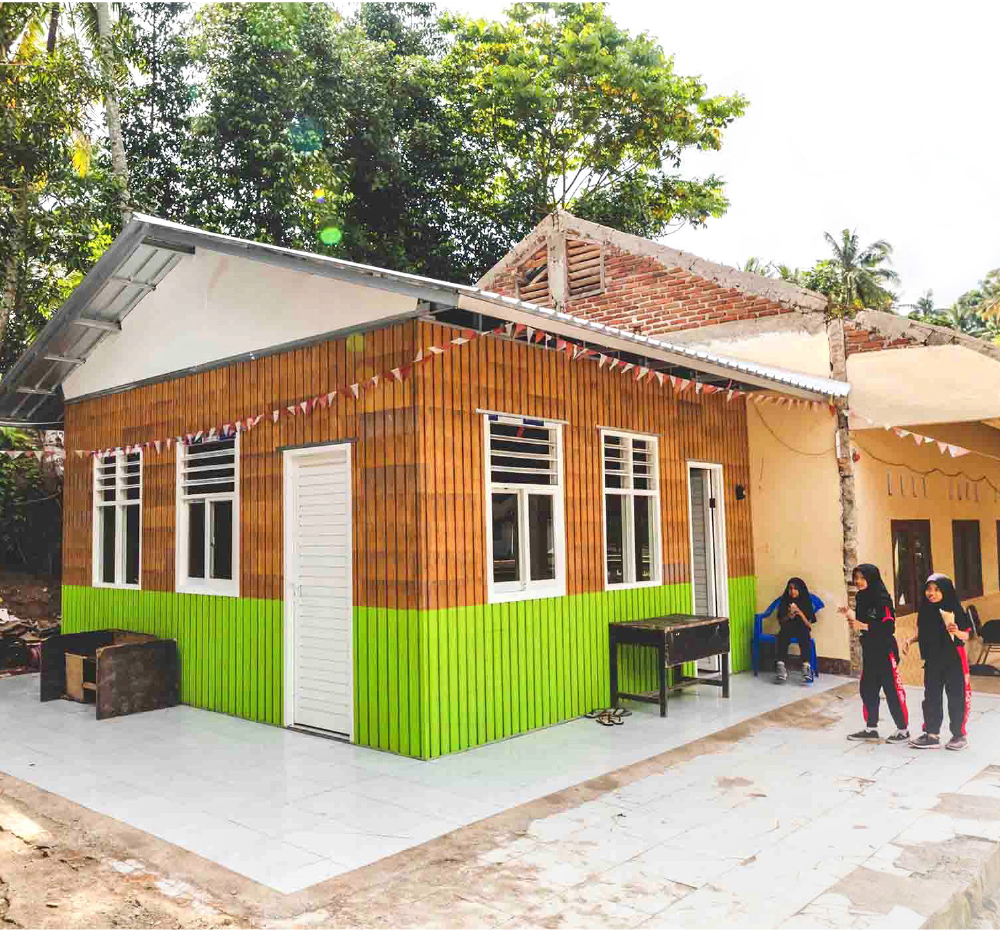

In 2021, the world’s first Block School was built with concrete foundation, steel rods and U-profiles to reinforce the structure, and a galvanised steel roof, glass windows and wooden doors to complete the building.

The 300sqm, five-classroom school building took just six days to construct (a task that would normally take three to six months for a brick and mortar building) and used 15 tonnes of plastic waste in the form of the blocks. The building was completed in June, and students started learning in their new school towards the end of the year when Covid-19 restrictions were lifted.

The organisation is also building houses using the same Block Solutions system. A home with two bedrooms, kitchen and toilet also takes six days to construct and removes one to three tonnes of plastic waste.

“We are building Block Homes for families who lost their homes in earthquakes and also low-income homes in high poverty areas,” said Duncan.

“The feedback has been very positive, and the locals have been happy with their new schools.”

The Indonesian government has endorsed the continued construction of Block Schools and Block Homes, and there are also plans to build public toilets, libraries and administration buildings using this technology.

The blocks are currently being shipped to Indonesia from Finland, which adds to the cost and timeframe of each project. However, it’s hoped that the construction of a local factory to produce the blocks in Indonesia will remedy this.

In November last year, a Letter of Intent was signed between Classroom of Hope, Block Solutions, investors, the Government of Nusa Tenggara Barat and representatives from the Australian Consulate and Finnish Embassy to signify a unified approach to building Asia’s first Block Solutions factory in Lombok.

“We have secured impact investment to build Asia Pacific’s first Block Solutions factory. We broke ground in February and hope to get the factory up and running by late 2022, producing blocks from locally sourced materials,” said Duncan.

Once the local factory is established, more schools and homes will be built, with plastic waste being removed directly from the local area to create the blocks.

Currently, 6.8 million tonnes of plastic is generated every year across Indonesia. Almost half of this is burnt, polluting the air with toxic fumes, while significant amounts end up in oceans, harming marine life and polluting coastlines, or being dumped in landfills.

“We intend to build four schools and 10 homes per month using blocks, and the Block Schools programme will build 200 schools serving 35,000 students over five-and-a-half years,” said Duncan.

“The 200 schools will remove about 3,000 tonnes of recycled plastic waste from the environment. The pipeline of 4,000 homes would serve 24,000 people over 10 years and remove 12,000 tonnes of recycled plastic waste.

“To date, we have built two Block Schools and two Block Homes. Our third school is being completed and we plan to build another three more schools with blocks from Finland to ensure sufficient building contractors are in place when the factory is finished.”

Classroom of Hope is currently seeking donors to fund the final phase of their capacity-building programme, which involves funding and building Block Schools and Block Homes to train many local contractors, and equip them with adequate knowledge in this innovative technology before the factory opens.

“Right now, on an average, a Block School costs about $60,000 and we are raising funds for eight more schools,” adds Duncan.

More information on Classroom of Hope at www.classroomofhope.org

Duncan can be reached at duncan.ward@classroomofhope.org

Reproduced from Rotary Down Under